EMS-8000 / EMS-9000

EyeMagic is a manufacturer of high performance and precission laser scanning systems.

The EMS-8000 as well as EMS-9000 series combine the flagship models of their product line.

EMS-8000 are equipped with mirrors for medium sized beams while EMS-9000 scanners are for large sized beams up to 10mm (square beam).

A special Ultrawide (UW) version of EMS-8000 offers a stunning 90x90° scan field capability.

Galvo Motor

- Low inductance coreless design for the fastest acceleration.

- Unparalleled heat transfer from coil to case, thanks to a novel bonding technique.

- Greatly increased ball bearing lifetime, using an "inside-out" ball preloading.

- High precision monolithic differential position detector cancels mismatch between discreet elements.

- Position detector amplifier is built into the scanner, giving high S/N ratio while avoiding the need for cumbersome dual shielded cables.

Mirrors

- Fused silica substrate with whiteligt dielectric, YAG or CO2 coatings, flatness l/4 over 10mm diameter.

- Mirrors are designed and cut/milled inhouse of EyeMagic. EyeMagic developed a special CNC setup for cutting and 3D milling of mirror sheets, with 0.01mm precision.

- Unique back thinned mirrors with ceramic center supports, offer low inertia and high stiffness. This translates to higher speeds, lower heat load for the motors and out-of-band resonances.

- Oversized mirror design to support "square" beam profiles from diode matrix lasers.

- Ultrawide version of EMS-8000: Special mirror set to support 90x90° scan field with up to 4.5mm apertures.

Servo Driver

- Digital dual axis servo driver. Small dimensions, similar to most analog drivers on the market.

- Modified PID based control with extra filters and prediction enhancements.

- Canceling of mirror or rotor resonances without a notch-filter.

- Scanner position calculation using signal ratio method. No analog components (AGC) to hold the excitation led steady, keeping drifts to a minimum.

- Pincushion and f-theta distortion correction in realtime, using mathematical calculations (not matrix tables and fit curves). Ideal for additive manufacturing. The system designer does not have to cope with complex routines in his control software. For laser display, it makes the projection "square", much like a video projector.

- Motor protection routine de-tunes the servo when overloaded and keeps the power to the coil at safe levels.

- Integrated scan safety routine for laser display, blocks the laser when the beam velocity drops below a certain limit. Threshold speed and activation time are adjustable via USB.

- Two general purpose outputs, activated from specific patterns being sent to the driver. Control devices or energize actuators for "beam table" type effects in laser display, without extra setup.

- Ultrawide version of EMS-8000: Special tuning for 35k ILDA speed with excellent large angle performance.

Specification

| Power requirements | +/- 24V DC, 2.5A per rail (EMS-8000), 3.5A per rail (EMS-9000) |

| Control voltage | +/- 5V differential, +/-10V single ended |

| Scan field | 54° optical (EMS-8000/EMS-9000) 90° optical (EMS-8000 UW) |

| Linearity | 99.9% over 40° optical |

| Pincushion/F-Theta correction | 99.5% over 40° optical |

| Small step response | 4.5mm(UW): 270µsec (35k 8° ILDA) 5mm: 150µsec (60k 8° ILDA) 6.5mm: 220µsec (40k 8° ILDA) 8.3mm: 240µsec (33k 8° ILDA) 10mm: 250µsec (30k 8° ILDA) |

| Coil resistance | 2.2 Ohms (EMS-8000) 1.6 Ohms (EMS-9000) |

| Realtime position out | +/- 10V |

| Beam velocity flag out | TTL low at low speed, TTL high at high speed |

| Auxiliary outputs | TTL high when servo detects a <2% sized pattern positioned at one of the 4 corners of the scan field. Left side activates out1, right side activated out2. |

| Data connection | Micro USB, MS Windows application |

Downloads

Article in Shop

Components

High performance scanning systems for beams up to 10mm. Made in Greece.

(MwSt. excl.)

Price without discount1.150,00 €

Compatible Accessories

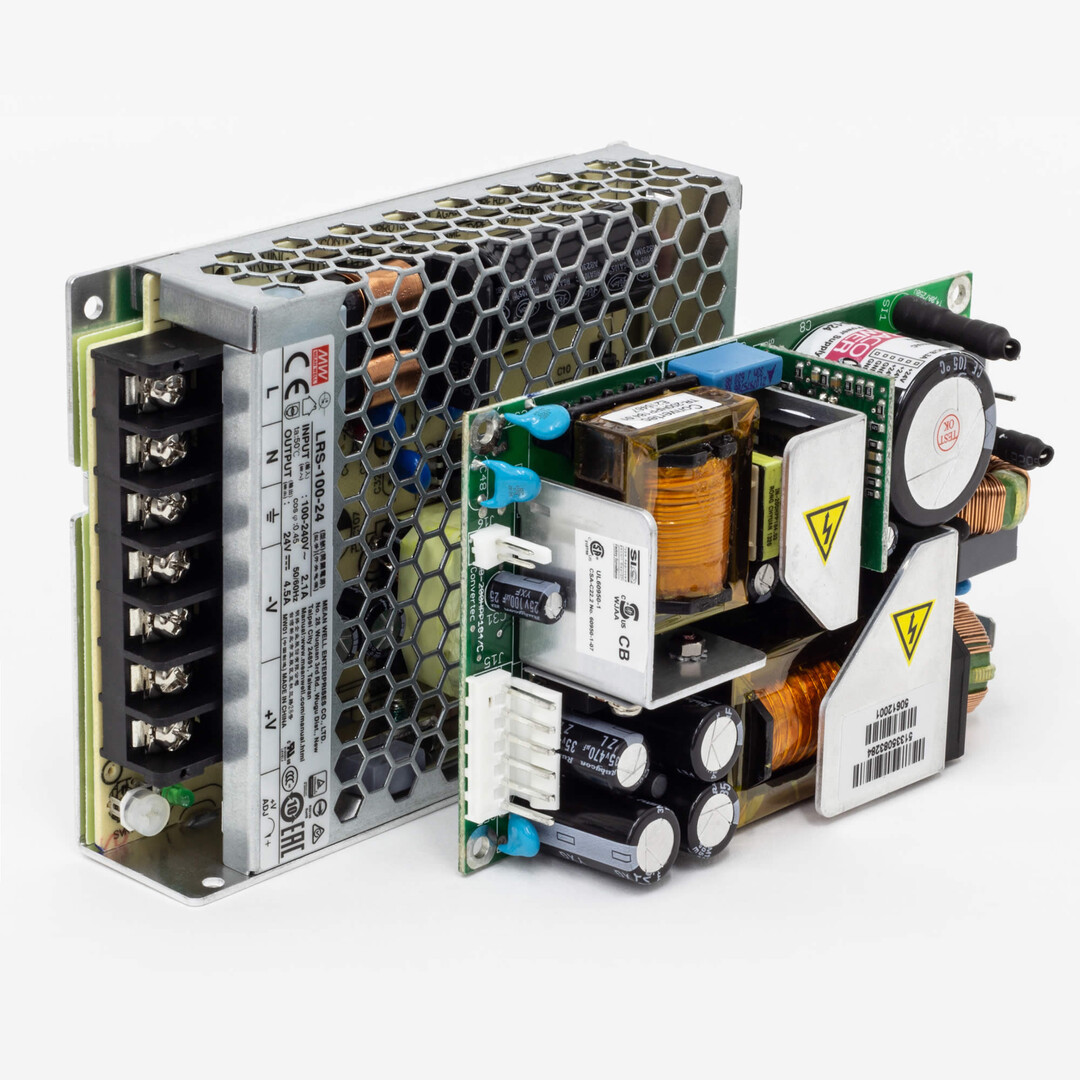

Components

Power supply for laser applications.

(MwSt. excl.)

Price without discount69,00 €